Chengye - Nail Tech Titan

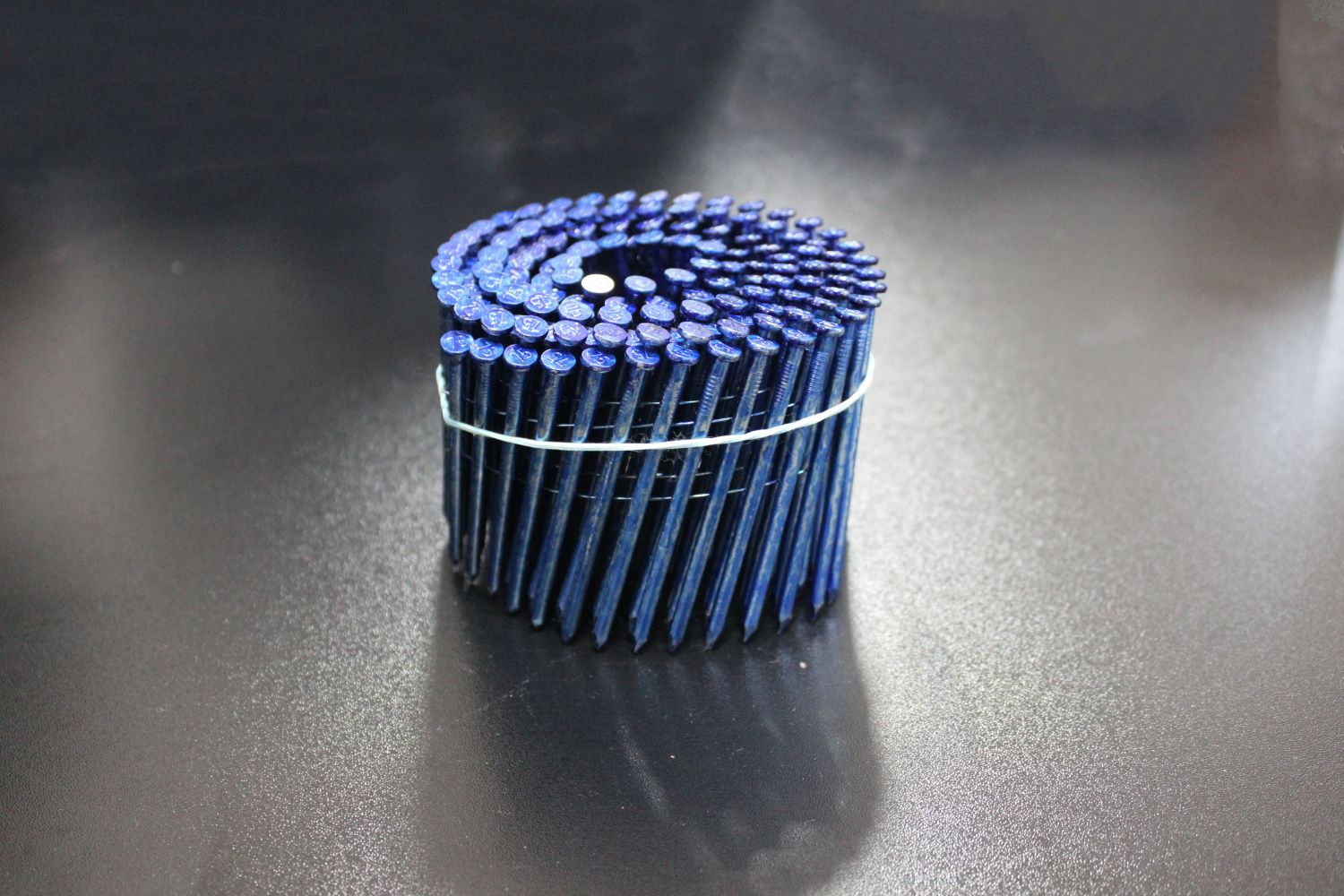

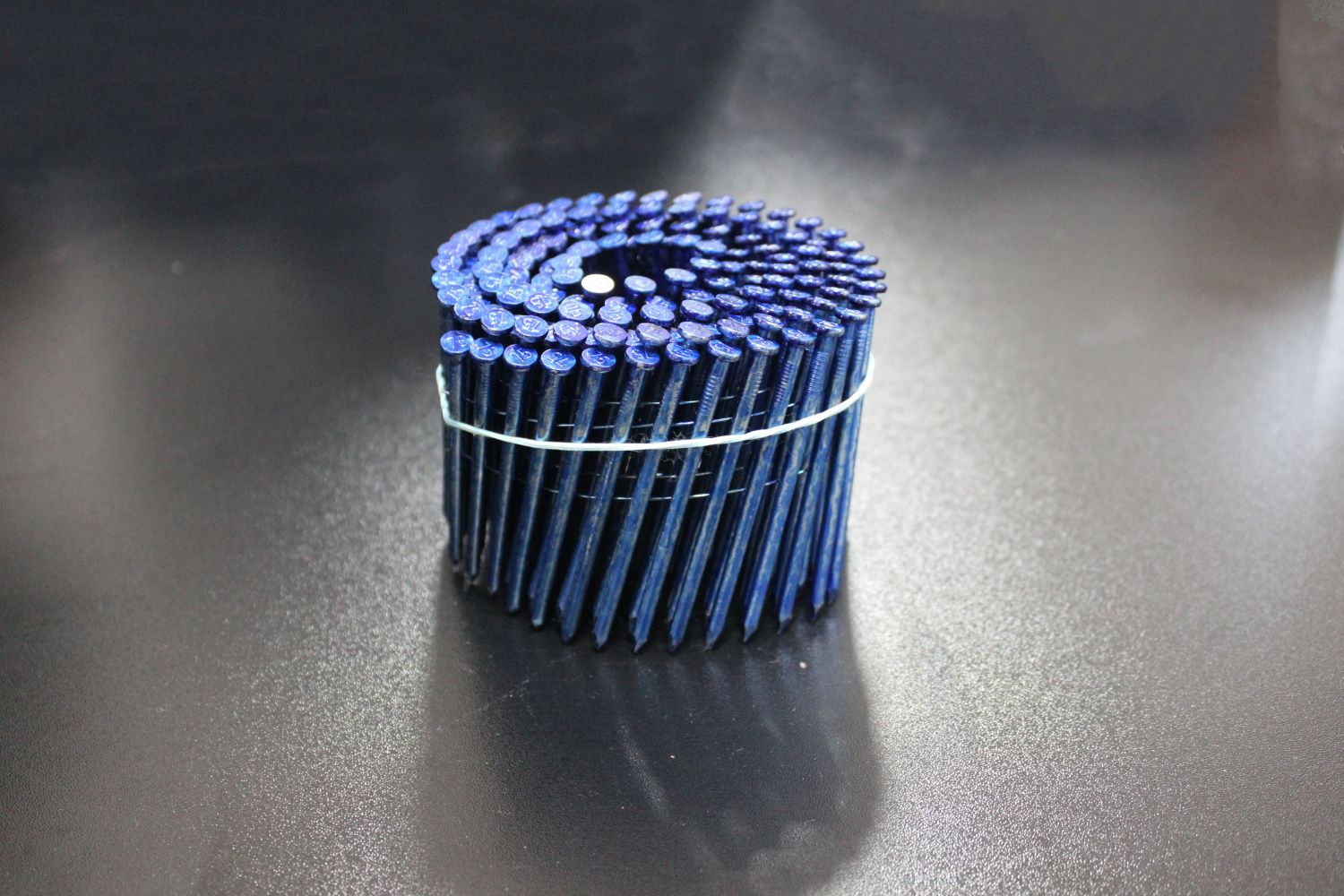

In the high-stakes world of construction fastening, where every strike demands precision and every joint must endure, Chengye stands as a global powerhouse. As a leading manufacturer in China, the brand redefines durability with its durable wire coil nails, heavy-duty coil nails CN75, high-performance nail fasteners, and precision wire coil nails for construction—products engineered to outlast extreme conditions while meeting the exacting demands of modern builders.

At the heart of Chengye’s innovation lies its heavy-duty coil nails CN75, a benchmark for industrial-grade fastening. Designed for applications like roof truss assembly, subfloor sheathing, and engineered wood framing, these nails feature a 25° angled head and a 0.120-inch shank diameter, striking the ideal balance between penetration power and holding strength. Tested to withstand 1,500 lbs of lateral pull-out force (per ASTM D1761 standards), the CN75 series ensures structural integrity in hurricane-prone zones and seismic regions alike—a testament to China’s manufacturers’ ability to merge raw power with precision engineering.

For contractors seeking custom solutions, Chengye’s precision wire coil nails for construction offer unmatched adaptability. Whether a client requires galvanized nails for marine-grade plywood, epoxy-coated variants for treated lumber, or ring-shanked designs for acoustic ceiling tiles, the brand’s in-house metallurgists and tooling experts collaborate to deliver bespoke fasteners. Operating from ISO 9001-certified facilities in China, Chengye can modify nail length (from 1.5” to 3.5”), head style, and even wire gauge within 48 hours of approval—a game-changer for projects with tight deadlines or specialized requirements.

The brand’s durable wire coil nails redefine longevity. Crafted from Q195 carbon steel and subjected to a triple-tempering process, these nails resist bending, shearing, and corrosion 30% longer than industry averages. A case in point: A major U.S. modular home builder reduced warranty claims by 45% after switching to Chengye’s nails, which maintained their grip even in regions with high humidity and freeze-thaw cycles. Such performance is underpinned by Chengye’s proprietary "Cold-Bond" adhesive coating, which minimizes misfires and jams in pneumatic nailers—a common headache for manufacturers worldwide.

Chengye’s high-performance nail fasteners also shine in specialized applications. Its "Heli-Shank" series, featuring a spiral-grooved profile, increases withdrawal resistance by 200% in OSB and plywood, making it ideal for shear walls and braced frames. Meanwhile, the "Arctic-Grade" line, treated with a zinc-aluminum alloy, remains malleable at -40°C, eliminating brittleness in cold-storage construction or polar region projects. These innovations, rooted in China’s manufacturing R&D, have cemented Chengye’s reputation as a problem-solver for niche markets.

Sustainability is another Chengye hallmark. The brand’s eco-coil nails use 30% recycled steel scrap without compromising strength, while its "Green-Coat" electro-galvanization process reduces water usage by 50% compared to traditional hot-dip methods. Clients in LEED-certified projects and green building initiatives increasingly opt for Chengye’s fasteners, which meet Cradle-to-Cradle Material Health Certification standards.

Global industries have embraced Chengye’s expertise. A Middle Eastern oil-and-gas contractor deployed the brand’s heavy-duty coil nails CN75 to secure insulation panels in 120°C desiccant dryers, while a European modular furniture maker integrated Chengye’s custom micro-coil nails for knockdown joints, slashing assembly time by 30%. Such partnerships highlight the brand’s ability to translate China’s manufacturing scale into tailored solutions.

Logistical agility further sets Chengye apart. With regional distribution hubs in Dubai, Houston, and Rotterdam, the brand ensures 98% on-time delivery rates for orders of any size. A South American truss manufacturer, for instance, reduced inventory costs by 25% by leveraging Chengye’s vendor-managed inventory (VMI) program, which syncs replenishment with production schedules.

As construction evolves toward automation and sustainability, Chengye innovates in lockstep. Prototypes include smart nails embedded with NFC chips for real-time quality tracking and biodegradable collated strips for zero-waste job sites. Such foresight, paired with the brand’s agile custom production, positions it as the future-ready partner for an industry in flux.

For builders demanding more than commodity fasteners, Chengye offers a strategic edge—one rooted in China’s manufacturing excellence yet tailored to global challenges. Whether it’s a CN75 nail that defies hurricane winds, a custom fastener for a high-rise curtain wall, or an eco-friendly solution for sustainable housing, the brand delivers fastening that builds trust.